How to Choose the Right Fabric Light Box For You

There are many types of Fabric Light Boxes on the market. They are mainly classified by frame thickness, such as 60mm, 80mm, 85mm, and 120mm. How do you choose a suitable and cost-effective Fabric Light Box based on your event or trade show needs? This article will help you understand the aspects of size, thickness, and frame materials.

What is a Fabric Light Box?

For those not familiar with Fabric Light Boxes customers, here is a simple introduction. A Fabric Light Box uses fabric graphics instead of glass or acrylic, so it gets its name. Since the fabric graphic has a SEG silicone strip sewn around the edges, it can be inserted into the lightbox frame grooves, so it is also called an SEG Light Box. With its bright, premium, and vibrant visual effect, it is widely used in shop windows, trade shows, events, and showroom displays.

Common Fabric Light Box Types on the Market and Their Pros & Cons:

Fabric Light Boxesare mainly grouped by frame thickness (60mm, 80mm, 85mm, 120mm). Light boxes with the same thickness have similar prices, so this makes classification easier. Below are the usage scenarios、 pros, and cons of different thickness options:

1.60mm Fabric Light Box

A 60mm Fabric Light Box refers to a light box with a 60mm frame thickness. The most common type on the market is the freestanding light box. Lintel can produce freestanding,wall-mounted, and hanging light boxes, all using Lintel’s global patented buckle-lock structurefor tool-free assembly and graphic replacement.

Advantages:

① The 60mm Fabric Light Box uses backlit illuminationbecause of its thin frame. This ensures bright and clear graphic performance.

② Its price is lowerthan 80mm, 85mm, and 120mm light boxes.

③ The 60mm Fabric Light Box offers more flexible shapes and stronger customization. It supports freestanding, wall-mounted, and ceiling-mounted applications.

④ The frame is aluminum with an anodized finish, making it scratch-resistant for long-term use. The fabric graphic is B1 fire-rated and does not deform easily.

⑤ Suitable for long-term use.Assembly is tool-free, graphic replacement is easy, and the aluminum frame + fabric graphic is eco-friendly.

Disadvantages:

① Because it uses backlit illumination, it can only be single-sided, so its usage is more limited andmust be placed against a wall.

② Due to the thin 60mm frame, it cannot be used for large SEG backdrops. The heightshould not exceed 2m.

P.S. Lintel currently offers only one standard size for the 60mm Fabric Light Box. Parameters are listed below.

|

Item No. |

Size |

Packing Size |

N.W. |

G.W. |

PC/CTN |

|

LT-ALF60 |

85 x 200cm |

55x 33 x 110cm |

7.5 kgs |

9.5 kgs |

1ctn |

③ The backlit graphic of the 60mm Fabric Light Box can only be stored by rolling it up. It cannot be folded. Although the 60mm frame can reduce the packaging volume of the light box frame, the graphic packaging volume will still be larger.

Summary:

- The advantages of the 60mm Fabric Light Box are its slim frame, small footprint, flexible usage scenarios, and affordable price.

- The disadvantages are that it can only be single-sided, the size options are limited, and storing the backlit graphic is relatively inconvenient.

Suitable Users / Scenarios:

- The 60mm Fabric Light Box is suitable for users who prioritize long-term use and donotrequire frequent attendance at exhibitions or events.

- It is ideal for ceiling decoration, wall-mounted advertising, or permanent retail store branding displays. You can simply change the graphic based on seasons or promotions.

- It is a light box that does not require hiring professional installers. You can directly install Wall-mounted light boxes and ceiling light boxes

2.80mm / 85mm Fabric Light Box

The 80mm / 85mm Fabric Light Box refers to fabric light boxes with an 80mm or 85mm frame thickness.

Why do we introduce these two thicknesses together?Because the Lintel 85mm Fabric Light Box corresponds to the 80mm Fabric Light Box on the market.

What is the difference between the two? What are their respective pros and cons? Keep reading to learn more:

Comparison: 85mm Fabric Light Box vs. 80mm Fabric Light Box

Similarities:

① Both use aluminum light box frames and SEG graphics. Assembly requires no tools, and graphics can be changed easily.

② Both use rotatable feet, making storage convenient and reducing packaging space.

③ Both Fabric Light Boxes can reach up to 2.5m in height and 1m in width.

P.S. Below are the sizes of the Lintel 85mm Fabric Light Box vs. the 80mm Fabric Light Box:

|

|

85mm Fabric Light Box |

80mm Fabric Light Box |

|

Length |

85cm \100cm |

85cm \100cm |

|

Height |

200cm \230cm \250cm |

200cm \250cm |

|

Custom sizes |

Support |

\ |

④ Both are edgelit light boxes, and both can be made as double-sided graphic light boxes.

Differences:

① TheLintel 85mm Fabric Light Boxuses an oxidized aluminum surface, which is resistant to scratches. The SEG graphic passes the B1 fire-resistant test and does not shrink or deformwith long-term use.

The 80mm Fabric Light Boxeson the market vary in quality. Some suppliers do not use oxidized aluminum or fire-resistant treatment. You need to check carefully whether these two processes are included before purchasing.

② The Lintel 85mm Fabric Light Boxuses a patented buckle-locking structure, allowing power to pass between frames without extra DC cables.

The 80mm Fabric Light Boxeson the market use direct insert connect, inserting plastic parts into the frame groove. Because of this structure, they require extra DC cables, and shadows may appear on the graphic after lighting. It is recommended to request more customer cases when purchasing.

③ The LED strips of the Lintel 85mm Fabric Light Boxareflush with the frame and embedded inside the structure. This prevents damage during trans and improves the overall appearance. The downside is that the profile becomes thicker — this is why Lintel uses an 85mm frame.

The LEDs of the 80mm Fabric Light Box are protruding. The advantage is a thinner profile, but LEDs are easy to hit or damage during transportation.

④ The Linte l85mm Fabric Light Box has pre-installed magnetic strips on the frame sides. The advantage is that you can connect frames magnetically without any tools to form a large backdrop, or use corner connectors to assemble a small trade show booth. The downside is that the price is slightly higher.

Most 80mm Fabric Light Boxes on the market do not have magnetic strips pre-installed, so they cannot be magnetically connected to a large backdrop. If you later purchase an 80mm model with a magnetic connection, it cannot be used together with the earlier non-magnetic ones. The advantage is that the price is cheaper than the Lintel 85mm Fabric Light Box.

Most 80mm Fabric Light Boxes on the market do not have magnetic strips pre-installed, so they cannot be magnetically connected to a large backdrop. If you later purchase an 80mm model with a magnetic connection, it cannot be used together with the earlier non-magnetic ones. The advantage is that the price is cheaper than the Lintel 85mm Fabric Light Box.

This is also why many customers ask why the Lintel 85mm version is more expensive than others.

Summary:

- The Lintel 85mm Fabric Light Box offers more size options,easier assembly, and magnetic connection, but the price is slightly higher.

- The 80mm Fabric Light Box has a thinner profile,smaller footprint, and lower price, but it cannot be magnetically connected, the LEDs protrude(requiring careful transport), and fire-resistant and oxidation processes must be checked before buying.

Tips: Lintel offers an80mm wall-mounted fabric light box, with larger sizes than the 60mm wall-mounted light box.

3.120mm Fabric Light Box

The 120mm Fabric Light Box refers to a fabric light box with a 120mm profile thickness. This product is generally used for trade show booths,retail window displays, and large events. It is designed for large-sized advertising displays.

Currently, the main types on the market are:

- Direct-insert light box

- Wrench-locking light box

- Lintel patented buckle-locking light box

The key differences and pros/cons are as follows:

Similarities:

① The LEDs are all embedded inside the frame, preventing damage during trans.

② All models can be assembled in sections,reducing packaging volume and making transportation easier.

Differences:

① Although all LEDs are embedded, Lintel uses a flush-mounted method to avoid bumps during transport. This design makes LED replacement easier— if an LED is damaged, you only need to replace the LED strip, not the entire frame.

② Lintel’s patented buckle-locking structure allows tool-free assembly. Even though the frame is sectional, it forms a tight structure after assembly and is easy to disassemblefor replacement.

The direct-insert structure also allows tool-free assemblyby inserting two frame sections together. Assembly and disassembly are easy, but because there is no locking structure, the frames may separate during carry.

The wrench-locking structure connects two frames and then locks them with a wrench. The frames will not separateduring handling (but the feet are direct-insert and may fall off during handling). However, assembly and disassembly are more time-consuming than the other two types.

③ Thanks to the patented buckle-locking design, the Lintel 120mm Fabric Light Box supports modular assembly. The length can reach 6m or more (the longest customer project was 12m). The height can reach 3m, and support custom sizes (the 240mm Fabric Light Box can reach 4m in height).

The direct-insert and wrench-locking types can reach 3m in width and 2.5m in height.

The detailed size chart is shown below:

|

|

Direct insert lightbox |

Wrench-locking light box |

Buckle locking lightbox |

|

Length |

85/100/200/300cm |

50/85/100/200/300cm |

50/85/100/200/250/300/400/500/600cm |

|

Height |

100/150/200/225/250cm |

100/150/200/225/240/250cm |

50/100/200/225/250/300cm |

|

Custom sizes |

\ |

\ |

Support |

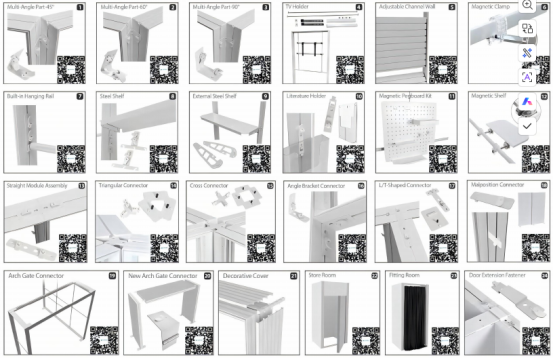

Ps. The Lintel 120mm Fabric Light Box can be equipped with functional accessories and angle connectors to assemble trade show booths or retail display stands.

④ Besides straight fabric light boxes, the Lintel 120mm Fabric Light Box can also be made as a curved fabric light box. The direct-insert and wrench-locking types can only be made as straight fabric light boxes.

Summary:

- The Direct insert light box is very easy to assemble and disassemble, and the LEDs are embedded inside the frame to prevent impact damage. The downside is that the frames may separate during carry, and the LED strips are not easy to replace when damaged.

- The Wrench-locking light box can be assembled and disassembled without tools, and the LEDs are also embedded inside the frame to prevent damage. The downside is that the assembly process is more complicated, and the LED strips are not easy to replace.

- The Buckle locking lightbox has patented technology, giving dealers and agents a competitive advantage. It can be assembled and disassembled without tools, and the frames will not separate during carry. The LEDs are flush with the frame, preventing impact damage. At the same time, it offers more size options and more versatile application scenarios.

These are the introductions to the common fabric light boxes on the market. Based on the above, do you know how to choose the right light box according to your event?

If you are interested in purchasing or becoming a dealer of fabric light boxes, feel free to contact us at email: [email protected]

People Also Ask:

Q1: Are fabric light boxes easy to install?

A1: Yes. They are very easy.

Lintel fabric light boxes use the Global Patent tool-free structures——buckle-locking designs. Modular and simple to set up. Even a 3×6m booth can be assembled in less than one hour.

Q2: How is the fabric light box graphic installed?

A2: The graphic has a silicone edge (SEG). You press the silicone edge into the groove of the light box frame. Fabric light box becomes tight, flat, and seamless. Graphics can be changed anytime. No tools needed.

Q3: How big of a light box do I need?

A3: It depends on how you use it:

1. For retail walls, ceilings, or backlit displays, 60mm fabric light box is enough.

2. For freestanding displays, you can choose 85mm fabric light box.

3. For trade show booths or large backdrops, you can choose 120mm modular fabric light box.

4. If you need sizes over 3m height or 6m width, only Lintel 120mm modular fabric light box supports this.

5. If you want magnetic connection, only the Lintel 85mm fabric light box offers this.

Tell me your booth size or space, and I can match the best model.

Q4: Are the light boxes energy-efficient?

A4: Yes.We use high-quality LED strips with long lifetimes. They are bright, stable, and energy-saving. All fabric light boxes offer strong brightness with low power use.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

DA

DA

FI

FI

NO

NO

SV

SV

TL

TL

BG

BG

HR

HR

CS

CS

NL

NL

EL

EL

HI

HI

PL

PL

RO

RO

IW

IW

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

MT

MT

TH

TH

MS

MS

GA

GA

IS

IS

AZ

AZ

KA

KA

BN

BN

MN

MN